Bush & Wilton began as a foundry which dates to 1783 in Bristol, England. We already had an extensive range of heavy-duty valves and was well established supplying the Cement, Plastic and Petrochemical industries. We supplied valves throughout the World for varied tasks in the most arduous conditions and for many of the foremost names in the process Industry.

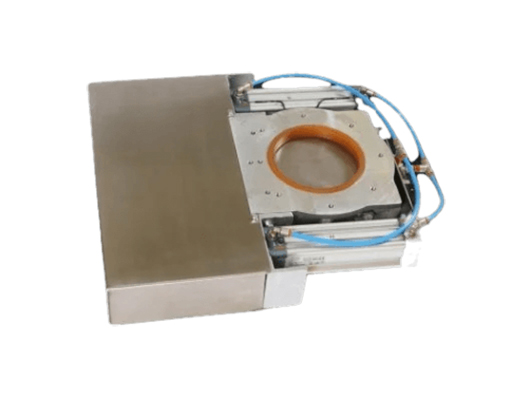

IFU Rotary Valve

Bush & Wiltons IFU Rotary Airlocks are rugged airlocks offering high capacities by virtue of having a large bore diameter relative to the inlet size. Available with circular flanges to suit common industrial standards (ASA 150lb, DIN PN10, JIS 10K etc.), they are designed for use under gravity, pressure and vacuum conditions. They are suitable for metering a wide range of dry solids, granular, pelleted and powdered type materials from the outlets of silos, hoppers, cyclones, mixers, weighers, etc. An extensive range of options is available. These airlocks are interchangeable with ‘legacy’ ‘IF’ series airlocks in most cases.

MSRP 'MULTIPLEX' Rotary Valve

The MSRP ‘Multiplex’ Parallel Bore Rotary Airlock is the all-rounder of the range. Featuring round / square combination flanges on the inlet and outlet, speeding selection and installation. Designed for use under gravity, pressure and vacuum conditions. Suitable for a wide range of dry solids, granular, pelleted and powdered type materials from the outlets of silos, hopper, cyclones, mixers, weighers etc. A maximum number of blades remain in contact with body at one time without affecting throughput. Substantial throat opening at valve entry allows high pocket filling efficiency. Robust body construction prevents distortion. An extensive range of options is available.

MSRT Tapered Bore Rotary Valve

The MSRT Tapered Bore Rotary Airlock (Formerly ‘SR’ Series) allows the clearance between the rotor and the body to be adjusted with the airlock in situ, without the need for disassembly. Flanges follow the ‘Multiplex’ concept of the ‘MSRP’ range.The tapered bore allows the clearance between the rotor and the body to be adjusted with the airlock in situ, without the need for disassembly. This can be used to compensate for wear, products with different handling characteristics, temperatures etc. The closed end tapered rotor is contained fully within the machined bore. This allows higher differential pressures to be accommodated compared to parallel bored airlocks with closed rotors. This is particularly useful where abrasive products need to be introduced into a pressurized system, as the rotor design keeps the product away from sensitive areas around the end covers and shaft seals, therefore reducing the risk of premature wear.

CD Flap Type Diverter Valve

CD Pressure Sealed Flap Type Conveying Diverters provide higher efficiency at substantially lower cost. Thse valves are virtually leakproof with both internal and external sealing. Very compact in size and interchangeable with existing products. What is truly outstanding about this line is the careful design and manufacture of the one moving element within the valve and improved access to this part for servicing. Standard sizes range from 50mm 200mm (2″ to 8″) in spigot design (CDS) and 50mm 300mm (2″ to 12″) in flange design (CDF).

- Cast iron body with mild steel flap assembly

- Cast aluminum with stainless steel flap assembly

- Cast stainless steel (316) with stainless steel flap assembly

- Polyurethane parabolic seal as standard, other options available

SBT Slide Gate Valve

- Sizes 6″ through 16″

- Aluminum or Stainless Steel construction.

- Food quality options available.

- A very compact design.

- Twin cylinders give positive closure against flowing product.

- Ideal for high frequency operations.

- Supplied with a spring return solenoid valve for control and reed switches for indication as standard.

- A variety of control and indication options are also available.

- ATEX Certified versions on request.